Edge Sealants

Edge-Flex 645Back to product index

Wood Edge Sealer Reduces Alkaline Water Absorption

Maximum performance edge sealer with form release agent.

Note: Choose Options to Buy Online

Additional Details

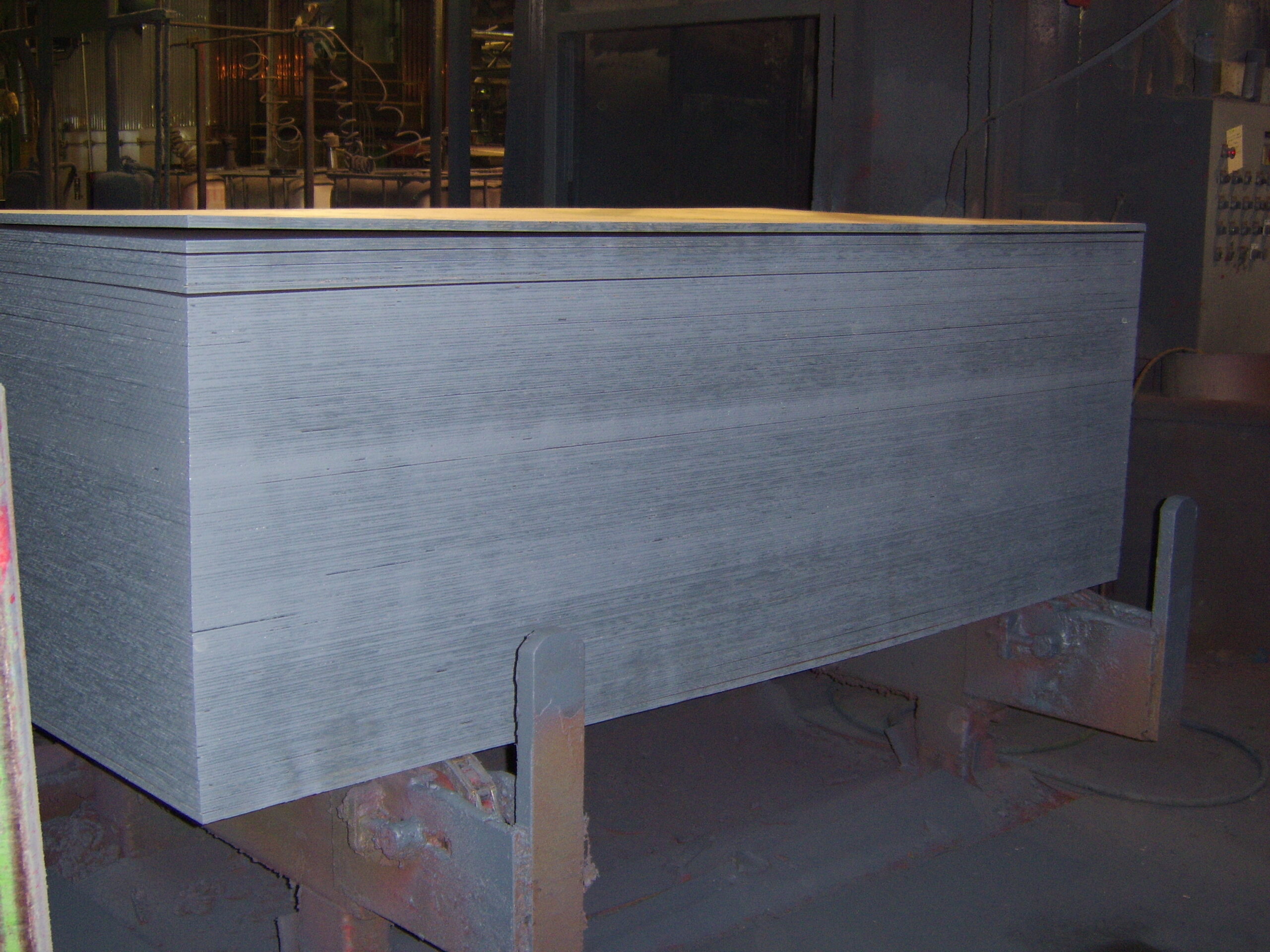

Edge-Flex 645 is a maximum performance edge sealer with form release agent that extends concrete forming panel life and reduces edge swell by reducing the absorption of alkaline bleed water through panel edges. Edge-Flex 645 is specially formulated with added release agent, making it ideal for use with all types of plywood, wafer-wood and OSB concrete forming panels.

By reducing edge swell and minimizing water absorption into panel edges, Edge-Flex 645 helps to increase panel longevity. Additionally, Edge-Flex 645 minimizes wood sugar and tannin migration, which reduces concrete color variations, staining and concrete surface dusting.

Applications

• In sealing the edges of all types of manufactured wood form panels, including plywood and oriented strand board (OSB) for concrete forming applications

• To seal all field-cut panel edges and snap-tie holes

• For reapplication over poor performing mill applied edge sealants

• Essential on all manufactured wood form panels for the production of architectural concrete

Advantages of this Edge Sealer with Form Release Agent

• Contains release agent to prevent concrete bonding

• Completely resistant to the higher alkalinity of many modern concrete mixes

• Minimizes alkaline water absorption through panel edges by up to 95%

• Minimizes water absorption into panel edges therefore minimizing wood sugar and tannin migration

• Reduces concrete color variations, staining, and surface dusting

• Significantly reduces panel edge swelling and related elevation variations from panel to panel

• Exceptional resistance to commonly used form oils and form release agents

• Greatly increases panel longevity

• Green Engineered™ − better for health and the environment

• Meets all federal and state VOC requirements

Resource Downloads

Product Data Sheet

English PDS - Edge-Flex 645

French PDS - Edge-Flex 645

Spanish PDS - Edge-Flex 645

Safety Data Sheets

English SDS - Edge-Flex 645

French SDS - Edge-Flex 645

Spanish SDS - Edge-Flex 645

English SDS - Stencil Paint (White)

Additional Documents

Forming Market Brochure

chemical solutions to concrete problems

chemical solutions to concrete problems