Nox-Crete Inc

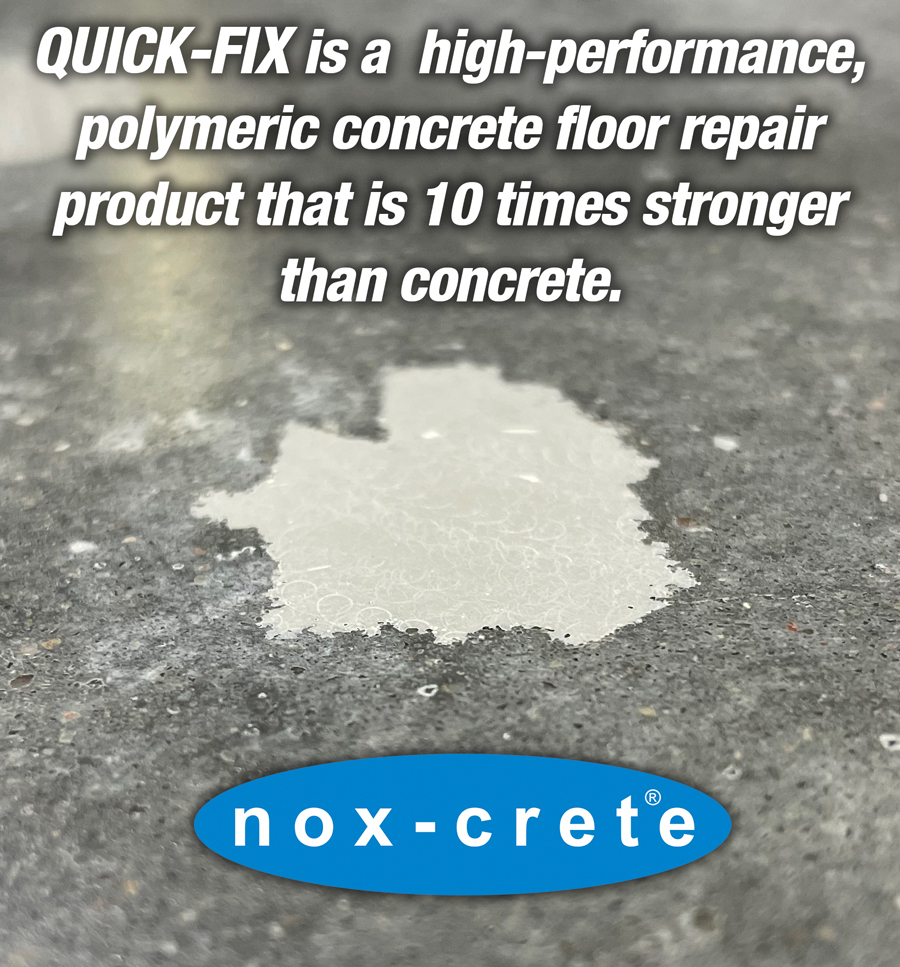

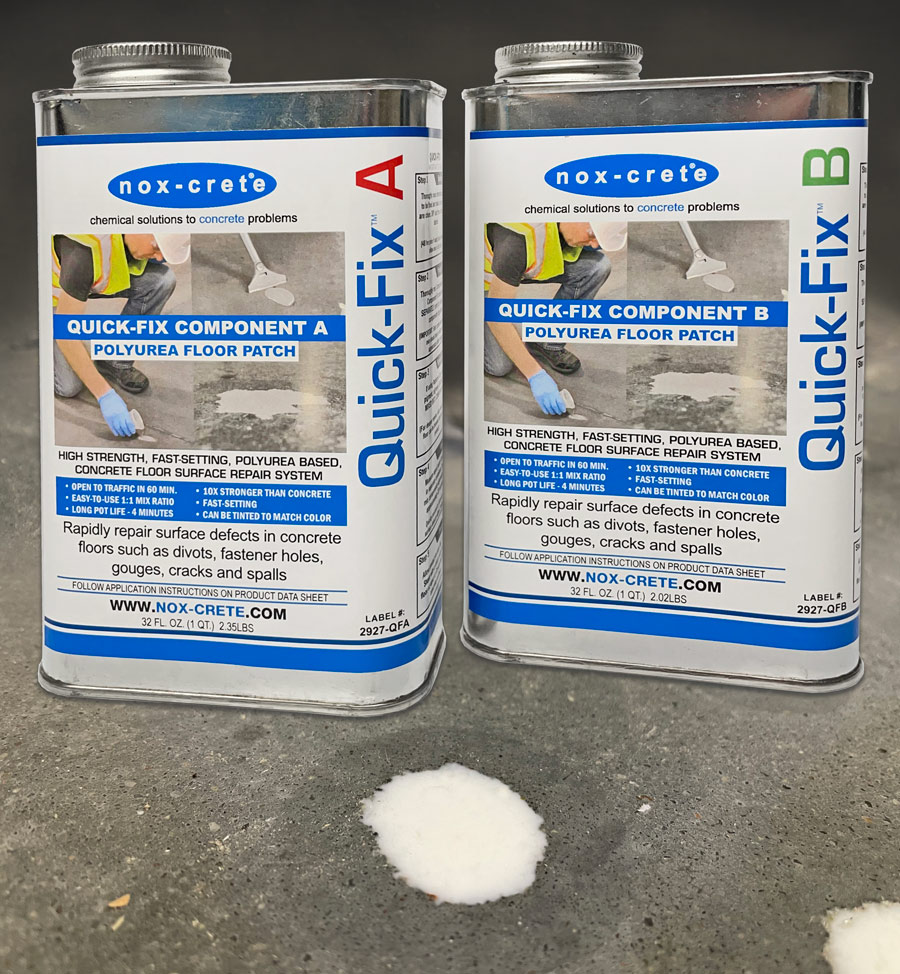

Quick-Fix

Price range: $241.48 through $958.02

High Strength, fast-setting, polyurea based, concrete floor surface repair system.

Transparent, High Strength, fast-setting, polyurea based, industrial concrete floor surface repair system that can be mixed with silica sand, silica flour or fumed silica or grey tint pack. 10 times stronger than concrete and open to traffic in a less than 60 minutes.

Find a Distributor

Nox-Crete highly recommends purchasing this product from a distributor to take advantage of the many benefits, including better pricing, in stock locally, no shipping charges, local service, in-person advice, and more! CLICK HERE for assistance