In the wake of New York City's revised building code that took effect in November 2022, architects and contractors face stricter fire-blocking requirements for exterior wall systems. With heightened scrutiny from the NYC Department of Buildings and Fire Department regarding combustible materials used in tall buildings, TigerLoc Plus emerges as an innovative solution that meets and exceeds these demanding standards.

NFPA 285 Compliance: A Critical Requirement

The NFPA 285 test has become a benchmark for safety in modern construction. This rigorous evaluation simulates a real-world fire scenario, requiring exterior wall assemblies to prevent flame spread, stop a fire from advancing between floors, block penetration through the wall, and maintain specific temperature thresholds.

For NYC projects, where aging building stock is being renovated, and new construction must adhere to stringent safety protocols, finding materials that achieve NFPA 285 compliance while offering versatility in design has been challenging—until now.

Why TigerLoc+ Stands Apart

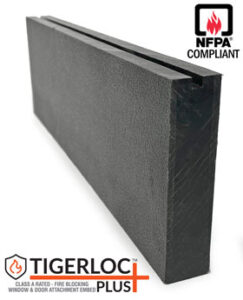

TigerLoc+ is a Class A Rated fire-blocking window and door attachment embed specifically engineered to replace traditional dimensional lumber in critical applications. As NYC increasingly embraces architectural precast concrete walls, TigerLoc+ provides the perfect complementary component for window and door details where fire resistance is paramount.

TigerLoc+ is a Class A Rated fire-blocking window and door attachment embed specifically engineered to replace traditional dimensional lumber in critical applications. As NYC increasingly embraces architectural precast concrete walls, TigerLoc+ provides the perfect complementary component for window and door details where fire resistance is paramount.

The product's patented structural design includes several advantages that make it ideal for NYC's demanding construction environment:

- NFPA 285 Compliance: Fully tested and certified, ensuring it meets NYC's latest fire-blocking requirements

- 100% Recyclable: Supports sustainability initiatives and green building certification

- Superior Moisture Resistance: Crucial in NYC's variable climate conditions

- Exceptional Durability: Won't twist, warp, or rot like traditional lumber

- UV Resistant: Unaffected by continuous sun exposure, heat, or cold

- Sound and Vibration Absorbent: Enhances building comfort and acoustic properties

Installation Benefits for NYC Contractors

In a city where construction efficiency translates directly to cost savings, TigerLoc+ offers significant advantages:

- Hazard Reduction: Conventional screws attach directly without creating hazardous silica dust from drilling into concrete

- Prefabricated Options: Available in multiple widths, eliminating costly job site fabrication

- Simple Integration: Easily attached to window and door edge forms

- Thermal Performance: Low thermal conductivity and high insulating value help meet energy code requirements

- Concrete Wythe Separation: Reduces cracking associated with thermal movement differences

Perfect for NYC's Construction Methods

As NYC increasingly adopts architectural precast concrete walls for new construction and retrofits, TigerLoc+ integrates seamlessly into this approach. The product's edge groove allows concrete to flow in for a secure hold, creating a robust connection that maintains the integrity of precast sections.

Applications Across NYC Projects

TigerLoc+ is specifically designed for use in critical areas of exterior wall assemblies:

- Window openings

- Mandoor openings

- Overhead door openings

- Panel edges and insulation caps

The TigerLoc+ Advantage for NYC Architects

Your spec, your reputation, your peace of mind—for architectural firms designing projects in NYC, TigerLoc+ offers a pre-tested solution that slots perfectly into your technical specifications, simplifying compliance while maintaining design flexibility. Early collaboration with Nox-Crete can identify methods that meet both aesthetic requirements and stringent NYC fire safety regulations.

TigerLoc+: The Final Word

In a city where code compliance is non-negotiable, and construction efficiency is essential, TigerLoc+ represents a significant advancement for NYC construction professionals. By incorporating this NFPA 285-compliant solution into your projects, you'll meet NYC's latest building code requirements while benefiting from improved installation efficiency, reduced maintenance concerns, and enhanced building performance.

For NYC architects and contractors navigating the challenges of the revised building code, TigerLoc+ isn't just an option—it's the solution you've been waiting for.

Get TigerLoc+

TigerLoc+ is immediately available. Nox-Crete offers a continuing education workshop about how to incorporate this new technology into your design method. Contact us today to learn more.

Mitch McCaulley, VP Business Development

Cell: 402.253.4033

Office: 402.341.2080

Email: mmccaulley@nox-crete.com

chemical solutions to concrete problems

chemical solutions to concrete problems

4. How did our product help make your project successful?

4. How did our product help make your project successful?

Reese was approached by a customer who topped a partial aggregate, broom-finished sidewalk at a residence with an acid stain. Upon completion, the stain turned a displeasing shade of orange. Reese was dispatched to fix the color issues.

Reese was approached by a customer who topped a partial aggregate, broom-finished sidewalk at a residence with an acid stain. Upon completion, the stain turned a displeasing shade of orange. Reese was dispatched to fix the color issues.